Introduction

India’s industrial heart beats in its chemical plants, water treatment facilities, and coastal ports, where tough conditions demand materials that last. FRP Moulded Gratings India have become a standout solution, leaving steel and concrete in the dust with their resilience, light weight, and cost savings. This article digs into what makes these gratings a must have, how they’re used, and why they’re reshaping India’s infrastructure game.

The Rise of FRP Moulded Gratings India

From chemical clusters in Gujarat to docklands in Mumbai, FRP Moulded Gratings India are solving issues traditional materials can't. Imagine corrosive chemicals, sea salt air, and endless heavy wear. These gratings don't just last they save money and grief, which is why they're a favorite among industries that can't spend time in downtime.

What Are FRP Moulded Gratings?

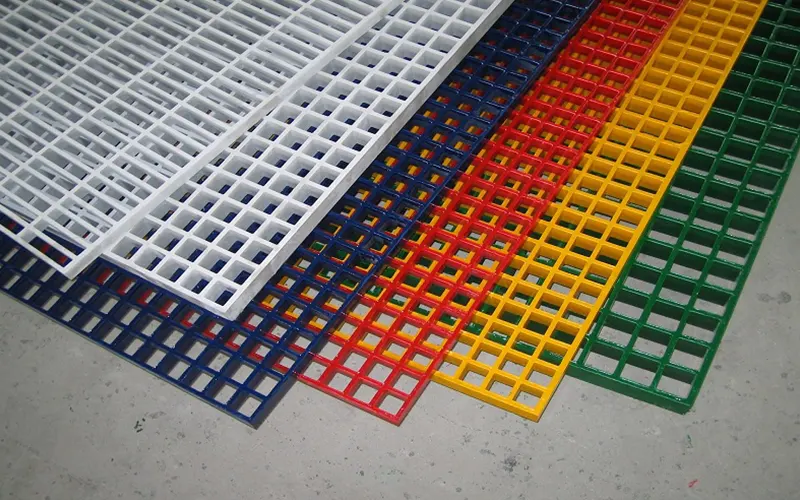

FRP Moulded Gratings India are materials made by interlacing continuous fiberglass rovings with thermosetting resins, e.g. polyester or vinylester, in a heated mould. This method of production results in one piece panel with a square mesh pattern that provides bi-directional strength. Usually, these gratings consist of 35% glass fiber and 65% resin that guarantee uniform load distribution and resistance to chemical and environmental degradation. Aeron Composite and Fiber Tech Composite, which are the manufacturers of such products, highlight their corrosion resistant feature and easy installation as their main selling points.

Why India’s Industries Are Shifting to FRP

Chemical plants and utilities in India deal with brutal conditions think acidic spills, humid coastal vibes, and heavy machinery. Steel rusts fast, and wood falls apart in wet settings. FRP gratings laugh off corrosion and wear, cutting down on replacement costs. Plus, they’re super light about a quarter of steel’s weight making them easier to haul and set up, especially for big projects in places like Ankleshwar or Chennai.

Key Properties Driving Adoption

The rise of FRP Moulded Gratings India comes down to their real-world advantages, perfectly matched to what modern industries need.

Corrosion Resistance

Chemical plants in places like Dahej handle nasty stuff like sulfuric acid. Steel and concrete crumble under that kind of attack, but FRP gratings, made with special resins like isophthalic or vinylester, just keep going. A Canadian plant using Fibergrate’s gratings ran smoothly for over 20 years with barely any upkeep, showing what’s possible in India’s tough setups.

Light but Tough

These gratings weigh way less than steel but can handle serious loads. That makes them perfect for walkways or platforms, where lugging heavy materials is a pain. Their strength in all directions means they won’t buckle, even under heavy equipment, saving time and cash on installation.

Safe and Sound

Unlike metal, FRP doesn’t conduct electricity, which is huge for electrical substations or telecom projects. Add in anti-slip surfaces gritted or concave and they cut down on slips in greasy or wet spots. This is a game changer for oil and gas sites, where safety is non-negotiable.

Barely Any Upkeep

Forget repainting or rust-proofing. FRP gratings stand up to UV rays, scorching heat, and chemical spills, often lasting over 20 years. That means less downtime and fewer budget hits, which industries love.

Applications in Chemical and Utility Infrastructure

FRP Moulded Gratings Manufacturers are showing up everywhere, proving their worth in some of India’s toughest infrastructure projects.

Chemical Plants

In Gujarat’s industrial zones, chemical facilities deal with corrosive acids daily. FRP gratings are used for floors, walkways, and trench covers in cooling towers, holding strong where others fail. Saumit InterGlobe makes gratings tailored for these rough environments, keeping workers safe and operations humming.

Water Treatment

India’s water plants, critical for tackling water shortages, face chlorine and other harsh chemicals. FRP gratings form walkways, stairs, and platforms that don’t corrode, ensuring clean water stays clean. They’re a mainstay in sewage treatment plants, helping India’s push for better water systems.

Oil and Gas

Offshore rigs in the Arabian Sea and onshore refineries need materials that can take saltwater and hydrogen sulfide. FRP gratings deliver, serving as reliable walkways and platforms. Their light weight makes setup a breeze in far-off spots, much like Fibergrate’s wins in the Gulf of Mexico.

Coastal and Marine

Ports like Mumbai and Visakhapatnam need materials that don’t flinch at saltwater. FRP gratings are used in gangways, footbridges, and walkways, standing up to waves and humidity. Tribeni Fiber notes their low heat transfer, keeping surfaces cool even in blazing sun.

Economic and Environmental Benefits

Beyond toughness, FRP Moulded Gratings India bring practical wins that fit India’s economic and green goals.

Cost-Effectiveness

Sure, FRP might cost as much as steel upfront, but the savings pile up. No constant repairs, and their light weight cuts installation costs. Bluemoon Fibre Tech says labor and equipment savings often make FRP cheaper overall than steel when you look at the big picture.

Going Green

Making FRP uses less energy than steel, and their long life means fewer replacements, less waste. Some makers, like EPP Composites, offer recyclable options, aligning with India’s sustainability drive.

Customization and Versatility

Indian manufacturers like Raval Composites customize gratings different mesh sizes, resins, even colors to match specific needs. Whether it’s a factory floor or a fancy architectural feature, they’ve got it covered.

Challenges and Solutions

Even with all their perks, FRP Moulded Gratings India face some hurdles, but the industry’s stepping up.

Initial Cost Perception

Some folks see FRP’s upfront cost and hesitate, thinking steel is cheaper. But when you factor in maintenance and replacements, FRP wins. Manufacturers are sharing real examples to show the long-term savings.

Awareness and Adoption

Smaller companies might not know FRP’s benefits yet. Firms like Aeron Composite are hitting the ground, showing off success stories to get more industries on board.

Technical Expertise

Using FRP right means picking the best resin and installing it properly. Manufacturers are offering training and support to make sure contractors and engineers nail it.

Future Outlook for FRP Moulded Gratings India

With India’s industries growing and sustainability in focus, FRP Moulded Grating exporters are set to shine. Programs like “Make in India” and smart city projects are crying out for materials like these.

Technological Advancements

New resins that resist fire and stronger designs are opening up more uses. Phenolic resins, for instance, make gratings safer for risky spots like offshore platforms, while anti-slip tech boosts safety.

Expanding Market Reach

As industries like pharma, food processing, and renewable energy jump on board, the market’s growing. Indian manufacturers are also shipping to places like Saudi Arabia, with companies like Amrock leading the way.

Case Studies of Success

A Gujarat chemical plant switched to FRP walkways and cut maintenance costs by 40% over five years. A Chennai water plant slashed installation time by 30% thanks to FRP’s light weight. These stories are pushing more industries to make the leap.

Wrapping It Up

FRP Moulded Gratings India are changing the game for chemical and utility infrastructure. They stand up to corrosion, pack strength without the weight, and save on maintenance, making them perfect for India’s toughest settings. From chemical plants to coastal ports, they’re delivering reliability and savings, supporting the country’s big plans for sustainable growth. With new tech and growing buzz, these gratings are here to stay, building a stronger, smarter future for India’s industries.

Recent Post

Why FRP Pultruded Gratings are Transforming Industrial Flooring Solutions

Why FRP Moulded Gratings Are Transforming Chemical and Utility Infrastructure

Why Indian Industries Are Making the Shift to FRP Cable Trays and What It Means for the Future

Why FRP Pultruded Gratings Are Spearheading India's Anti Corrosion Revolution