Introduction

Corrosion eats away at India's industrial spine, from seaside piers to chemical factories, draining billions in replacement and repair. In this ongoing struggle, FRP pultruded gratings India have become a game-saver. Manufactured through a process of careful attention, such composite materials resist rugged conditions where steel succumbs, providing durability, safety, and economy. This article delves into FRP pultruded gratings India's strengths, uses, and the future, uncovering why they're propelling India's anti-corrosion charge with unstoppable strength.

The Power of FRP Pultruded Gratings

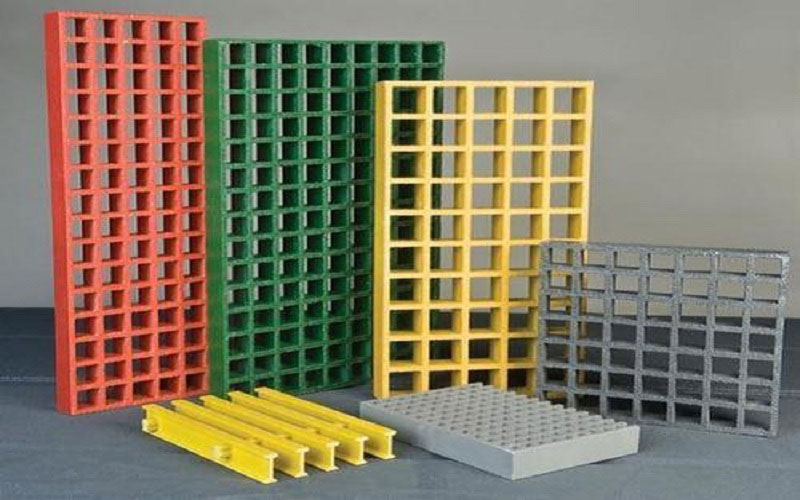

Throughout India's industrial belts, FRP pultruded gratings India are making headway as a higher-quality substitute for conventional products. Pulled out of a resin bath and formed into accurate profiles by pulling fiberglass strands, these gratings provide robustness and adaptability. Their popularity marks the trend away from solutions that do not survive India's harsh environments, from sea salt-laden coastal air to chemical-laden factories.

Corrosion: India’s Silent Infrastructure Threat

Corrosion doesn’t discriminate. It attacks steel walkways in Mumbai’s offshore platforms, erodes drainage systems in Bangalore’s treatment plants, and weakens railings in Vadodara’s chemical factories. India’s coastal regions, industrial zones, and tropical climate amplify the problem, with humidity and chemical exposure speeding up metal decay. FRP pultruded gratings India stand firm against these forces, resisting acids, alkalis, and saltwater without rusting or degrading.

How Pultrusion Makes the Difference

The pultrusion process lends FRP pultruded gratings India their signature strength. Fiberglass strands, oriented for ultimate toughness, are drawn through resin and shaped into grids or bars. This process produces gratings that can withstand heavy loads and long spans, as opposed to molded types. Manufacturers may alter resins—polyester for general-purpose application, vinyl ester for chemical applications, or phenolic for fire resistance—to suit particular requirements, making these gratings an ideal match for India's diverse industries.

Designed to Resist Corrosion

In environments such as Gujarat's chemical factories, where fumes full of acid are an everyday occurrence, FRP pultruded gratings with stand unscathed without even a whiff of rust. An industrial unit in Bharuch replaced steel catwalks with FRP and has not had to make replacements in more than a decade, cutting maintenance costs to shreds. The gratings shrug off abrasive chemicals and ocean air, and they're a natural choice for India's most challenging environments.

Light but Tough

Light as a quarter of steel's weight, FRP pultruded gratings India are simple to handle and install. One Chennai offshore platform replaced steel with FRP, reducing installation time by 25%. However, these gratings have metal's strength equivalent, tolerating heavy machinery and footfalls without a hitch.

Low Maintenance, High Durability

No more painting and rust-proofing forever. FRP pultruded gratings India are UV- and chemical-resistant and require minimum maintenance. One Delhi wastewater treatment plant utilized them as trench covers and has not had to replace any panels in nine years, realizing huge savings.

Safety First

Industrial accidents are not only expensive—they're hazardous. FRP pultruded gratings India mitigate dangers with non-conductive surfaces, ideal for Hyderabad's power plants where electrical risks are present. Their anti-slip surfaces bear down on boots even in oily or wet environments, such as in Jamnagar's refineries, which ensures workers remain steady.

Why Industries Are Switching

The popularity of FRP pultruded gratings India isn't all about withstanding corrosion. Their practical advantage is revolutionizing the way industries think about infrastructure, from cost-effectiveness to worker safety.

Fire and Heat Resistance

Certain FRP pultruded gratings India employs phenolic resins to resist high temperatures, a blessing for thermal power plants in Tamil Nadu. These gratings remain robust at temperatures that would deform metal, guaranteeing safety where it counts.

Where FRP Gratings Excel in India

From factories to sea piers, FRP pultruded gratings India are making their mark in industries, tackling challenges metals can't meet.

Chemical and petroleum industries depend on FRP pultruded gratings India for stair treads and walkways. In Vadodara, a facility replaced rusty steel platforms with FRP, reducing maintenance expenses by one-third. The gratings support heavy loads and corrosive spills, ensuring operations remain smooth and safe.

India's extensive coastline requires products that resist saltwater beating. FRP pultruded grating manufacturers are deployed at docks and offshore rigs in Visakhapatnam, where they withstand corrosion and UV exposure. A Kochi pier had a 15-year life with no significant repairs, a far cry from the constant maintenance of steel.

In Delhi and other cities, wastewater facilities utilize FRP pultruded gratings India as trench covers and flooring. They are open in design and allow water to flow through but fight chemical corrosion. One Bangalore plant cut 25% of its maintenance needs by replacing with FRP, passing tough environmental measures without frequent replacements.

Rajasthan and Gujarat solar and wind farms utilize FRP pultruded gratings India as maintenance platforms. Being non-conductive, they negate electrical hazards, and being light in weight, they facilitate quicker installation. One solar plant reduced setup time by 20% and improved project efficiency.

Pedestrian bridges and railway platforms in Mumbai and Kolkata are using FRP pultruded gratings India due to their durability and simplicity of installation. Their weather resistance makes them withstand heavy foot traffic as well as monsoon rains.

Extending the Frontiers with Innovation

Indian manufacturers are leading the way in developing FRP pultruded gratings India, making them stronger, more flexible, and greener. These innovations are spreading into new industries.

Smarter Resin Systems

New resins, such as vinyl ester and phenolic, enhance the performance of FRP pultruded gratings India. Vinyl ester manages harsh chemicals in Gujarat factories, and phenolic withstands fire in Uttar Pradesh power plants. These resins extend the boundaries of what FRP can accomplish, opening up doors to niche applications.

Custom Designs for Every Need

Companies such as FiberTech Composite PVT. LTD. customize FRP pultruded gratings India to particular projects. Heavy-duty bars hold heavy loads of cars in parking garages, and T-profiles are used to cover vast distances in factory walkways. This kind of customization allows each industry to receive precisely what it requires.

A Greener Choice

Sustainability is important, and FRP pultruded gratings India provide it. They produce with less waste than metal production, and they have such a long lifespan that they reduce replacements. One Gujarat solar farm lowered its environmental impact 30% by using FRP instead of steel to meet India's green objectives.

Overcoming Barriers to Adoption

In spite of their advantages, FRP pultruded gratings India encounter barriers to broader adoption. Overcoming them is the key to their expansion.

Upfront Expenses vs. Long-Term Savings

Yes, FRP pultruded gratings India will be more expensive in the beginning than steel. But the calculations add up in the long run. A Mumbai marine project saved 35% on lifetime costs by making the change to FRP, validating the investment through reduced maintenance and longer lifespan.

Spreading the Word

Small companies usually aren't aware of FRP pultruded gratings India. Manufacturers are coming forward with workshops and on-the-ground demos, demonstrating how FRP beats metal. Collaborations with industry associations are spreading the word.

Getting Installation Right

Poor installation can ruin good materials. FRP pultruded gratings India require proper installation to sparkle. Producers now provide comprehensive instructions and training so that projects such as Chennai-based offshore platforms remain durable.

Case Studies: Real Stories, Real Results

The effectiveness of FRP pultruded gratings India is exemplified in real-life scenarios wherein they're revolutionizing the game.

Gujarat Petrochemical Plant

A Vadodara factory abandoned steel for FRP pultruded gratings India to manage acid spills. Maintenance expenses fell by 30%, and anti-slip surfaces protected workers better, justifying FRP in tough environments.

Mumbai Offshore Rig

An offshore rig in Mumbai used FRP pultruded gratings India for decking. The light weight reduced installation time by 20%, and corrosion protection saved millions over ten years in maintenance.

Chennai Wastewater Facility

A Chennai treatment plant utilized FRP pultruded gratings India for trench covers. Seven years of no maintenance saved 25% in costs and conformed to stringent environment regulations.

Rajasthan Solar Farm

A Rajasthan solar plant utilized FRP pultruded gratings India as maintenance platforms. Their non-conductive characteristics and light weight accelerated installation by 15%, enhancing safety and efficiency.

What's Next for FRP Gratings in India

The future is rosy for FRP pultruded gratings India, as India's infrastructure and industrial development drive demand. Their use in corrosion resistance is only expanding.

A Growing Market

As India constructs intelligent cities and expands renewable energy, FRP pultruded gratings India will witness enormous demand. The market will register a growth of 9% per annum, with increasing projects in marine, transport, and industrial segments.

Cutting-Edge Advances

Research is taking FRP pultruded gratings India forward with nano-enhanced resins and hybrid composites that increase strength and versatility. These advancements may see a place for FRP in high-tech applications such as aerospace or telecom.

Policy Support

Government policies to encourage sustainable infrastructure are a wind at the back of FRP pultruded gratings India. Improved standards, such as IS 6746, ensure quality, while green material incentives promote uptake.

Conclusion

FRP pultruded gratings India are not just a product—they're a solution to India's corrosion problem. Resistant to harsh environments, reducing costs, and enhancing safety, they form the building blocks of new age engineering. From chemical plants to coastal pier structures, they're witnessing their worth on a daily basis. As awareness and innovations increase, FRP pultruded gratings India will drive the movement towards a stronger, more durable industrial future.

Recent Post

Why FRP Pultruded Gratings are Transforming Industrial Flooring Solutions

Why FRP Moulded Gratings Are Transforming Chemical and Utility Infrastructure

Why Indian Industries Are Making the Shift to FRP Cable Trays and What It Means for the Future

Why FRP Pultruded Gratings Are Spearheading India's Anti Corrosion Revolution